MONOLITHIC INSULATION JOINTS

Nupros Inc. offers NUSEAL monolithic joints in various piping grade, pressure class, design factor design temp, corrosion allowance, testing requirements, joint length, electrical properties and coating thickness as per client's specification.

The Monolithic Isolation Joints offered by NUPROS INC. are manufactured using quality material and do not require any kind of maintenance.

The usage of monolithic isolating devices in cathodically protected systems is considered by NACE SP0286-2007.

Monolithic Isolation Joints that are used to provide electrical isolation and cathodic protections in pipeline, tanks and pumping station where petroleum gas & water are carrier fluids.

In addition, these Monolithic Isolation Joints are also used to provide electrical sectioning and passive protection against corrosion on inlet and outlet pipes of meters, tanks and pumping station.

TECHNICAL SPECIFICATION

Nupros Inc. offers NUSEAL monolithic joints in various piping grade, pressure class, design temp, corrosion allowance, testing requirements, joint length, electrical properties and coating thickness as per clients specification.

Sealing system offered by Nupros Inc. are set of O rings, sets of square seals or Useal for high pressure application.

BASIC TECHNICAL DATA SHEET

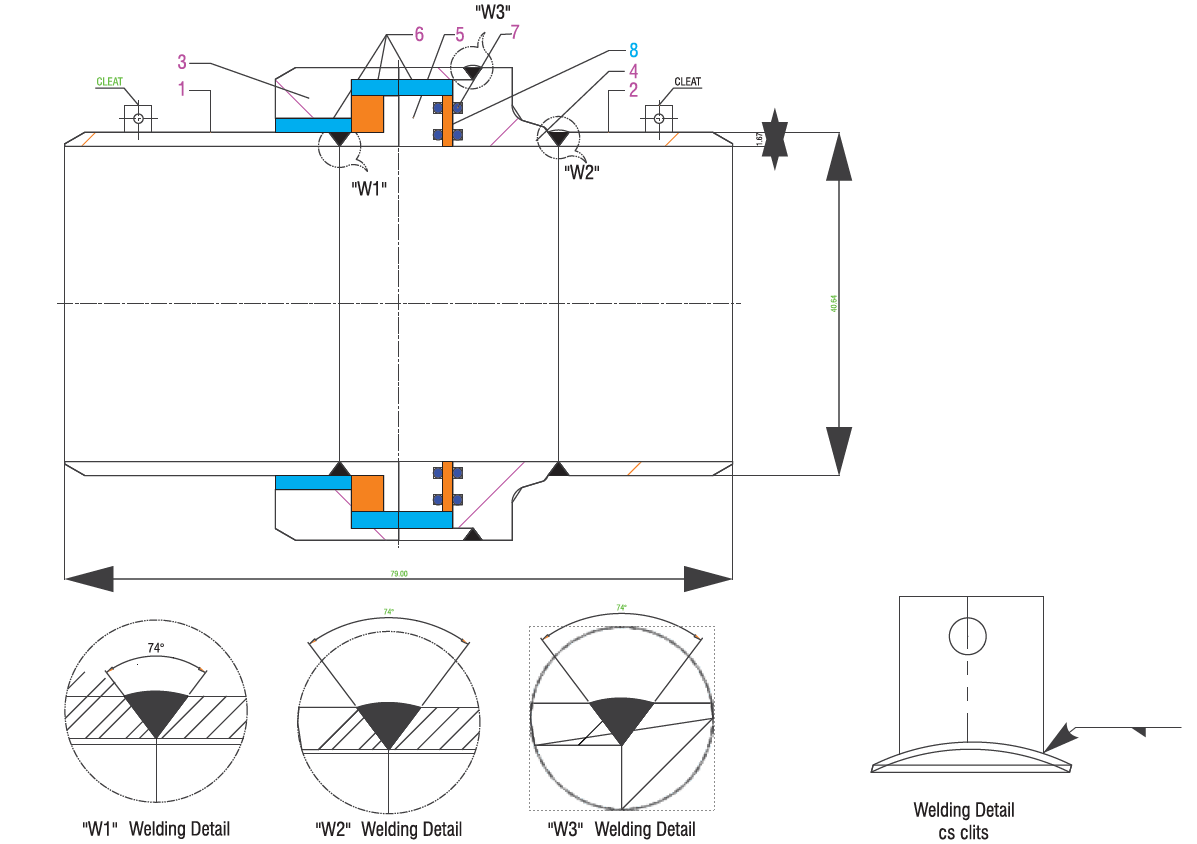

Nuseal Monolithic joints basic tech spec along with cross section view is as under

| CERTIFICATION | EN 10204 3.1 or 3.2 |

|---|---|

| NDT PUP Bevels | 100% MT/UT/ASME V – ASME VIII |

| NDT W3 Closure Weld | 100% MT/UT/ASME V – ASME VIII |

| NDT W1-W2 Butt Weld | 100% RT/UT/ASME V – ASME VIII |

| Pneumatic Test | >2 Bar 10 Min |

| Hydrostatic Test | At test Pressure or as per Customer requirements |

| Hydro- fatigue test | 5 Cycles at 80% to 90% TP or as per Customer requirements |

| Insulation Resistance | >25 Minimum |

| Dielectric Strength Test | 2 to 10 kv (AC) % 50Hz (1-5 min) |

| Design Code | ASME VIII D.I - ANSI B 31.8/4 |

| Design Factor | 0.2 to 0.6 |

| Max allowable loads | up to 95% SMYS-Based On Customer requirements |

| Insulation | NEMA G10/G11 Thermoseting Epoxy Composite |

| Internal Coating | >150 Micron |

| External Coating | >150 Micron |

PRODUCTION RANGE

| SIZE | From ½" up to 62" and over |

|---|---|

| RATING | From ANSI 150 to ANSI 2500, API 10000 and over |

| END CONNECTIONS | Butt welded, WNRF, RF, RTJ or per clients specifications |